Filter needle for glass ampule – Filter needles for glass ampules play a crucial role in various industries and applications. They provide a safe and effective method for filtering liquids and gases, ensuring the integrity and quality of products. This comprehensive guide delves into the world of filter needles, exploring their types, selection, use, maintenance, and market trends.

From defining the concept to discussing the latest advancements, this guide offers a thorough understanding of filter needles and their significance in modern science and industry.

Introduction

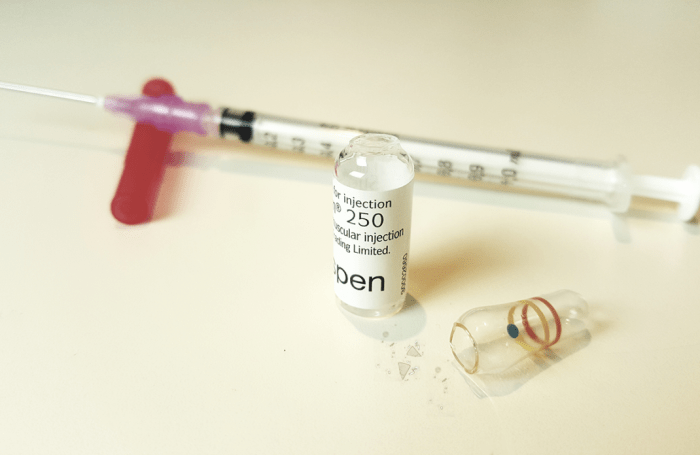

A filter needle for glass ampules is a specialized device used in the pharmaceutical industry for the filtration and transfer of sterile solutions into glass ampules.

It consists of a hollow needle with a filter membrane attached to its tip. The filter membrane is designed to trap particles and contaminants, ensuring the sterility and purity of the solution being transferred.

Materials Used

Filter needles for glass ampules are typically made from high-quality materials such as stainless steel, which provides strength and durability.

The filter membrane can be made from various materials, including polyethersulfone (PES), nylon, or polytetrafluoroethylene (PTFE), depending on the specific requirements of the application.

Types of Filter Needles

Filter needles are specialized needles used to filter liquids during the filling or dispensing process of glass ampules. They are designed to remove particles, contaminants, and microorganisms from the liquid, ensuring the purity and sterility of the final product. There are various types of filter needles available, each with unique characteristics and applications.

Syringe Filter Needles

Syringe filter needles are commonly used for small-volume filtration. They are attached to a syringe and can be used to filter liquids directly into the syringe or into a separate container. Syringe filter needles are available in a range of pore sizes, allowing for the removal of particles of different sizes.

In-Line Filter Needles

In-line filter needles are designed for use in fluid lines. They are typically used in larger-scale filtration applications, such as during the filling of glass ampules on production lines. In-line filter needles can handle higher flow rates and are available in various sizes and configurations to meet specific application requirements.

Vented Filter Needles

Vented filter needles are equipped with a vent that allows air to escape during filtration. This prevents the formation of air bubbles in the liquid, which can interfere with the filtration process. Vented filter needles are particularly useful for filtering liquids that tend to foam or produce gas.

Materials and Applications

Filter needles are typically made of stainless steel or polyethersulfone (PES). Stainless steel filter needles are more durable and can withstand higher pressures, while PES filter needles are more chemically resistant and suitable for use with a wider range of liquids.

Filter needles are used in various industries and applications, including:

- Pharmaceutical manufacturing

- Biotechnology

- Chemical processing

- Food and beverage industry

- Laboratory research

Selection and Use

Selecting and using the appropriate filter needle is crucial for effective and safe filtration of glass ampules. Here are the factors to consider and proper techniques to ensure optimal performance.

Factors to Consider, Filter needle for glass ampule

- Size and Type of Ampule:Choose a filter needle with a diameter that matches the opening of the ampule. Select the appropriate filter type (syringe or vacuum filtration) based on the specific application and sample volume.

- Sample Compatibility:Ensure the filter membrane material is compatible with the sample being filtered to prevent interactions or contamination.

- Filtration Efficiency:Consider the pore size of the filter membrane to achieve the desired level of filtration and particle removal.

- Safety Features:Look for filter needles with safety features such as a luer lock connection to prevent accidental disconnections and ensure a secure fit.

Proper Techniques

- Preparation:Inspect the filter needle for any damage or defects before use. Ensure the ampule is clean and free of any debris.

- Insertion:Carefully insert the filter needle into the ampule opening at a slight angle. Avoid touching the filter membrane with the needle to prevent clogging.

- Filtration:Apply gentle pressure to the syringe or vacuum line to draw the sample through the filter membrane. Monitor the flow rate to ensure optimal filtration.

- Removal:Once filtration is complete, slowly withdraw the filter needle from the ampule. Dispose of the filter needle properly according to laboratory protocols.

Safety Precautions

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Handle filter needles with care to avoid accidental punctures.

- Dispose of used filter needles in a sharps container to prevent injuries.

- Follow all laboratory safety protocols and guidelines when using filter needles.

Maintenance and Troubleshooting

Regular maintenance of filter needles is crucial to ensure their optimal performance and longevity. Proper cleaning and sterilization prevent contamination, blockages, and damage.

Cleaning and Sterilization

Clean filter needles thoroughly after each use. Disassemble the needle and soak the components in a suitable cleaning solution for the recommended duration. Rinse thoroughly with purified water and air dry. Sterilize the needle by autoclaving or using an appropriate chemical method.

Follow the manufacturer’s instructions carefully.

Troubleshooting

If you encounter any problems when using filter needles, here are some troubleshooting tips:

- Clogged needle:Replace the filter or clean the needle with a compatible solvent.

- Leaking needle:Tighten the connections or replace the O-rings.

- Slow filtration:Check for blockages in the filter or needle, or increase the pressure.

- Broken needle:Inspect the needle for damage and replace it if necessary.

Applications

Filter needles for glass ampules find widespread use across various industries and applications, offering unique benefits and advantages in specific scenarios.

Filter needles for glass ampules are essential tools for precision liquid handling, ensuring accurate and sterile transfer. They come in various sizes and materials to meet specific application requirements. Just like Val in a chorus line val monologue , who effortlessly moves between different roles, filter needles for glass ampules provide versatility in the laboratory, enabling researchers to handle a wide range of liquids with ease.

Pharmaceutical Industry

- Sterile filtration of injectable drugs, vaccines, and other pharmaceutical solutions.

- Removal of particulate matter and microorganisms to ensure product safety and efficacy.

- Accurate dispensing of precise volumes of fluids during drug administration.

Biotechnology Industry

- Sterilization of cell culture media, buffers, and other biological fluids.

- Filtration of samples for analysis and research purposes.

- Efficient separation of cells, proteins, and other biomolecules.

Chemical Industry

- Purification of solvents, reagents, and other chemical solutions.

- Removal of impurities and contaminants to improve product quality.

- Accurate dispensing of chemicals for analytical or synthesis purposes.

Environmental Monitoring

- Sampling and filtration of water, soil, and air for analysis.

- Detection of pollutants, microorganisms, and other contaminants.

- Monitoring environmental quality and assessing potential risks.

Market Trends: Filter Needle For Glass Ampule

The market for filter needles used in glass ampules is experiencing significant growth due to the increasing demand for injectable medications and the need for safe and effective drug delivery systems.

Several factors are driving this growth, including the rise of biologics, the increasing prevalence of chronic diseases, and the growing awareness of the importance of patient safety.

Advancements in Filter Needle Technology

The development of new filter needle technologies is also contributing to the growth of the market. These advancements include:

- The development of new filter materials that are more effective at removing contaminants

- The development of new needle designs that are less likely to cause pain or discomfort

- The development of new manufacturing processes that are more efficient and cost-effective

Opportunities and Challenges

The growth of the filter needle market is creating opportunities for new and existing companies. However, there are also some challenges that the industry must address, including:

- The need to meet the increasing demand for filter needles

- The need to develop new filter needle technologies that are even more effective and cost-effective

- The need to address the challenges of global competition

Questions Often Asked

What are the different types of filter needles available?

Filter needles come in various types, including syringe filters, bottle-top filters, and in-line filters. Each type is designed for specific applications and offers unique advantages.

How do I select the right filter needle for my application?

Consider factors such as the volume of liquid to be filtered, the desired filtration efficiency, and the compatibility of the filter material with the liquid.

How do I maintain and clean filter needles?

Regular cleaning and sterilization are crucial to ensure optimal performance and prevent contamination. Follow the manufacturer’s instructions for proper cleaning and sterilization procedures.