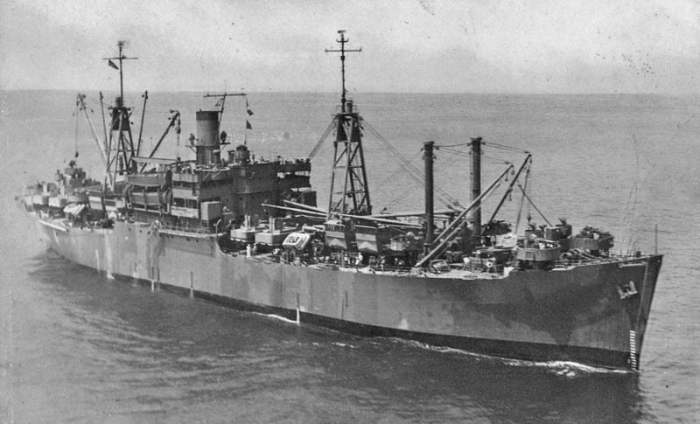

Most Liberty ships were hard to sink because they were welded. This unique design feature, along with the use of watertight compartments, contributed to the exceptional buoyancy and seaworthiness of these vessels, playing a pivotal role in World War II and beyond.

The welded steel hulls and watertight compartments provided Liberty ships with an unprecedented level of resilience, enabling them to withstand torpedo attacks and other damage that would have sunk other types of ships.

Design and Construction of Liberty Ships

Liberty ships were designed with several structural features that made them difficult to sink, including:

Welded Steel Hulls

Liberty ships were constructed using welded steel hulls instead of the traditional riveted hulls. This made the ships much stronger and more resistant to damage.

Watertight Compartments

The ships were also divided into multiple watertight compartments. This meant that if one compartment was flooded, the others would remain intact, keeping the ship afloat.

Buoyancy

The combination of the welded steel hulls and watertight compartments gave Liberty ships a high degree of buoyancy. This meant that they could withstand a significant amount of damage without sinking.

Materials and Manufacturing Techniques

Types of Steel

Liberty ships were constructed using a variety of steel grades, including mild steel, high-tensile steel, and alloy steel.

Welding Techniques

The ships were welded using a variety of techniques, including manual arc welding, submerged arc welding, and spot welding. These techniques produced strong, durable welds that contributed to the ships’ strength.

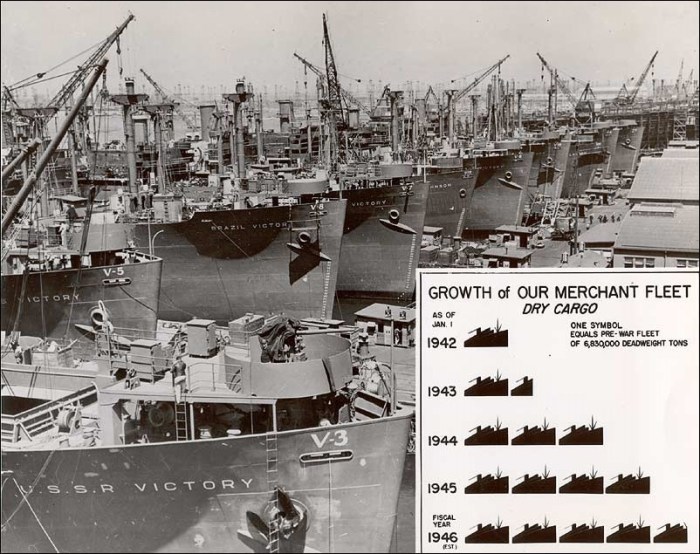

Prefabrication and Mass Production

Liberty ships were constructed using prefabrication and mass production techniques. This allowed the ships to be built quickly and efficiently.

Performance and Seaworthiness

Sinking Rate

Liberty ships had a very low sinking rate compared to other types of vessels. This was due to their strong construction and high buoyancy.

Torpedo Attacks

Liberty ships were able to withstand torpedo attacks and other damage due to their watertight compartments and welded steel hulls.

Seaworthiness

Liberty ships were known for their exceptional seaworthiness. They were able to operate in a variety of conditions, including rough seas and heavy weather.

Historical Significance: Most Liberty Ships Were Hard To Sink Because They Were

World War II, Most liberty ships were hard to sink because they were

Liberty ships played a vital role in World War II by transporting supplies to Allied forces. They were also used to transport troops and equipment.

Durability and Resilience

The durability and resilience of Liberty ships contributed to the Allied victory in World War II.

Legacy

Liberty ships continue to be remembered for their role in World War II and their impact on maritime history.

Top FAQs

Why were Liberty ships so hard to sink?

Liberty ships were hard to sink because of their welded steel hulls and watertight compartments, which provided exceptional buoyancy and resilience.

What was the significance of Liberty ships in World War II?

Liberty ships played a crucial role in World War II by transporting vital supplies to Allied forces, contributing to the Allied victory.

How did the design of Liberty ships contribute to their seaworthiness?

The welded steel hulls and watertight compartments of Liberty ships enhanced their seaworthiness, enabling them to withstand torpedo attacks and other damage.